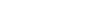

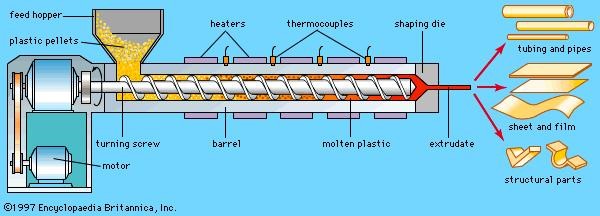

Slat Warehouse products are produced through a process of extrusion, where High Density Polyethylene (HDPE) pellets are melted and liquefied with a combination of heat and pressure, and then squeezed through a precision die which sets the plastic in the desired fence slat shape. This shape is then pulled through a series of water tanks to cool and set the shape permanently in place.

Slat Warehouse products are produced through a process of extrusion, where High Density Polyethylene (HDPE) pellets are melted and liquefied with a combination of heat and pressure, and then squeezed through a precision die which sets the plastic in the desired fence slat shape. This shape is then pulled through a series of water tanks to cool and set the shape permanently in place.

The ingredients of the HDPE material are designed and formulated to meet strict industry standards for processing and durability in a variety of environments. Specifically, for the Slat Warehouse product line, additives are included to provide consistent colors, and to enable the product to endure the harsh effects of ultra-violet impact from the sun. Additionally, HDPE is durable enough to withstand severe weather conditions, sand, most acids, petroleum distillates  and common environmental pollutants. These properties are commonly found in packaging from plastic bags to bottles and it boasts the reputation of being the most common plastic in the world.

and common environmental pollutants. These properties are commonly found in packaging from plastic bags to bottles and it boasts the reputation of being the most common plastic in the world.

Partners of Slat Warehouse have been intimately involved in the polymer extrusion business for over 30 years, developing a vast amount of experience in all types of plastics and processing methods. You can have confidence not only in the materials that are used for Slat Warehouse products, but equally in the care and professionalism of the people, machinery and manufacturing process of our partners.

(Graphic depicting the extrusion process)

Melt Index: (.08) A low melt index indicates improved stress and crack resistance.

Density: (.953) High Density for maximum stiffness without becoming brittle.

Minimum Temperature: (-75˚ F) Polyethylene will not soften and/or distort below this temperature when installed in the chain-link wire.

Maximum Temperature: (190˚ F) Polyethylene will not soften and/or distort below this temperature when installed in the chain-link wire.

Tensile Strength: (4,000 psi) Polyethylene will not suffer any distortions at lesser loads or impacts.